Diagnosis of the Electrohydraulic Power Steering Pump

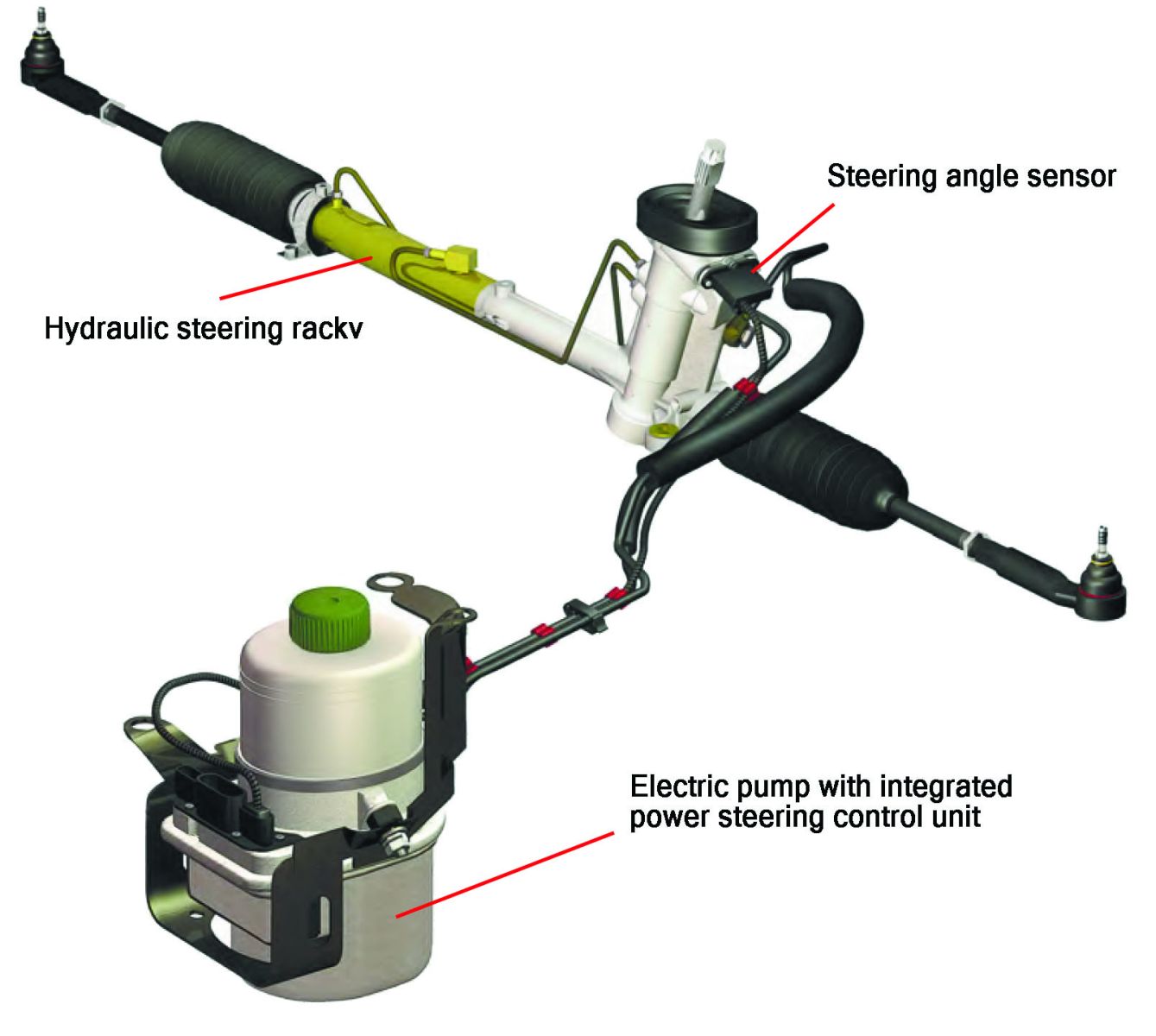

The electrohydraulic power steering pump (EHPS pump) is a complex and high-tech unit, the proper functioning of which directly affects driving comfort and safety. Its malfunctions may result from both mechanical and electronic issues. Many of these faults present similar symptoms: the steering wheel becomes heavy, the pump produces noise, or fault codes appear. To accurately identify the cause, professional diagnostics are required, in which the use of specialized equipment plays a key role.

Typical Malfunctions of EHPS Pumps

In practice, service specialists most often encounter the following problems:

1. Electric motor malfunction

The electric motor is the “heart” of the pump. Over time, it may fail for several reasons:

- wear of the brushes;

- bearing damage;

- overheating of the windings and inter-turn short circuits;

- commutator wear.

Such malfunctions are usually accompanied by a characteristic hum, vibration, or a complete failure of the pump to start.

2. Failure of the Electronic Control Unit (ECU)

The control unit regulates pump operation by maintaining optimal system pressure. Possible failures include:

- failure of power transistors;

- overheating or damage of microcircuits;

- software malfunctions.

These problems typically manifest as unstable pump operation, random shutdowns, or error codes stored in the ECU memory.

3. Mechanical Failures in the Hydraulic Section

This type of malfunction leads to reduced power steering efficiency and unusual noises when turning the wheel. The most common mechanical failures include:

- wear of vanes and the pump housing, resulting in pressure loss;

- fluid leaks through seals and fittings.

4. Electrical problems and wiring issues

Often, the pump failure is caused not by the pump itself but by external electrical circuits. As a result, communication with the pump via CAN, FlexRay, or PWM lines becomes impossible due to:

- damaged or broken wiring;

- oxidation of contacts in connectors.

Comprehensive diagnostics using MS561 PRO and MS511 testers

To accurately determine the cause of an EHPS pump malfunction, both the electrical and hydraulic parts must be tested. Full diagnostics can only be achieved through the combined use of two testers — MS561 PRO and MS511.

General view of the MS561 PRO and MS511 testers

When diagnosing an EHPS pump, the MS561 PRO tester is connected to the electrical circuit and allows determining whether the pump responds to power and control signals, as well as whether it provides correct parameters such as current consumption and voltage. Using the MS561 PRO tester, it is also possible to obtain information about control unit errors (DTC) and device data (VIN, firmware version). In addition, the MS561 PRO simulates a vehicle for the pump and can control its performance, which makes it possible to check the hydraulic part using the MS511 tester.

The MS511 tester, in turn:

- measures the pressure generated by the pump in various operating modes;

- measures fluid flow (discharge rate), which is essential for assessing pump performance;

- simulates turning the steering wheel to the extreme position using a built-in valve that restricts fluid flow — this makes it possible to test the operation of valves and evaluate the pump’s response to increased load;

- helps identify fluid leaks and reduced hydraulic performance.

Advantages of MSG Equipment testers

- High diagnostic accuracy enabled by advanced technologies.

- User-friendly interface with data logging for detailed analysis.

- Support for a wide range of EPS pump models.

- Updatable software to expand the list of supported units.

- Compatibility with multiple communication protocols: CAN, CAN-FD, and FlexRay.

Conclusion

Diagnosing EHPS pumps is a challenging task without the proper tools. The combined use of the MS561 PRO and MS511 testers enables comprehensive diagnostics of the EHPS pump, helping identify both obvious and hidden faults, and make a well-grounded decision on whether to repair or replace the unit.