Main Parameters of Diagnostics for Electric Vehicle and Hybrid Batteries

Modern electric and hybrid vehicles are unimaginable without efficient and reliable batteries. These energy storage systems are not only the source of power for vehicle propulsion but also one of the most expensive components of the car. During the diagnostics of a high-voltage battery, several parameters are taken into account to objectively assess its current condition and forecast further operation.

Key Parameters of High-Voltage Batteries

Let us consider the key parameters that specialists use when inspecting and evaluating the condition of electric and hybrid vehicle batteries.

1. State of Charge (SOC)

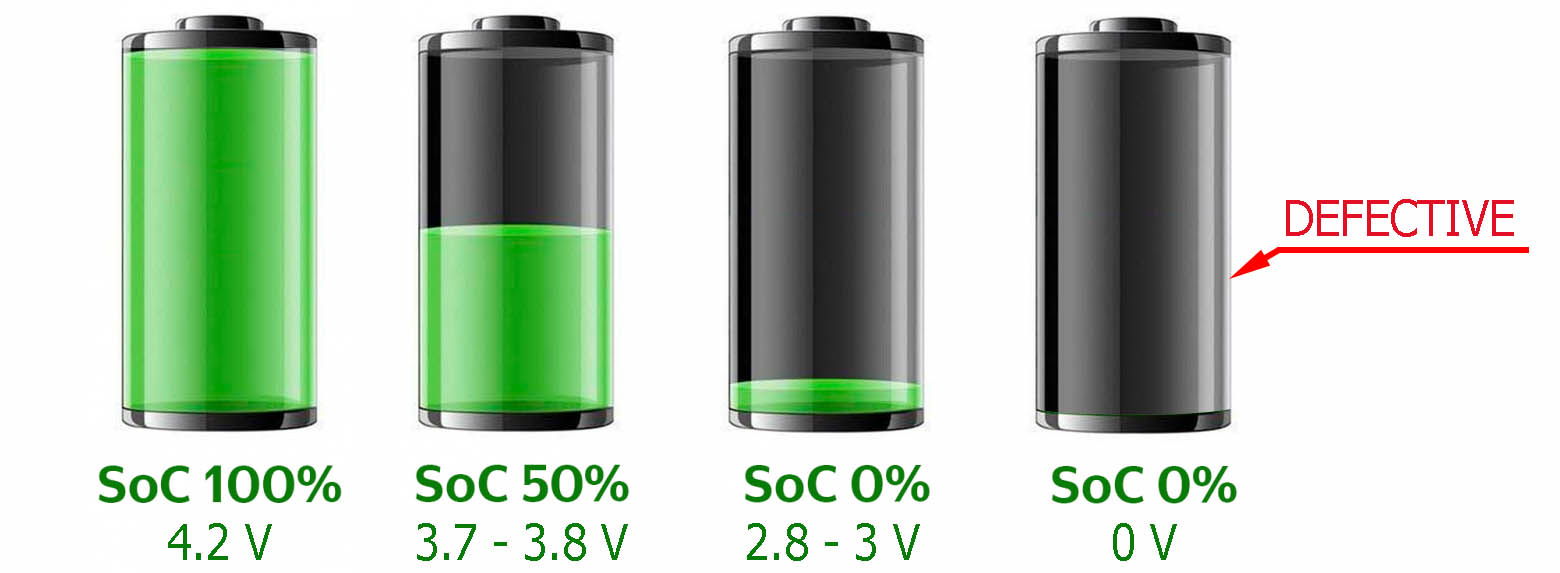

The State of Charge (SOC) reflects the amount of energy currently available. This parameter is an important diagnostic indicator, as deviations in its values may point to a problem. The SOC is usually expressed as a percentage, where 0% corresponds to a fully discharged battery and 100% to a fully charged one. In practice, SOC is determined by measuring voltage, since lithium-ion batteries exhibit an almost linear correlation between these parameters. If the voltage measured on an individual battery module is significantly lower than the others, that module is likely defective. It is also important to remember that every battery has a defined operating voltage range. If the module voltage drops below the minimum permissible level, the module is most likely faulty.

2. State of Health (SOH)

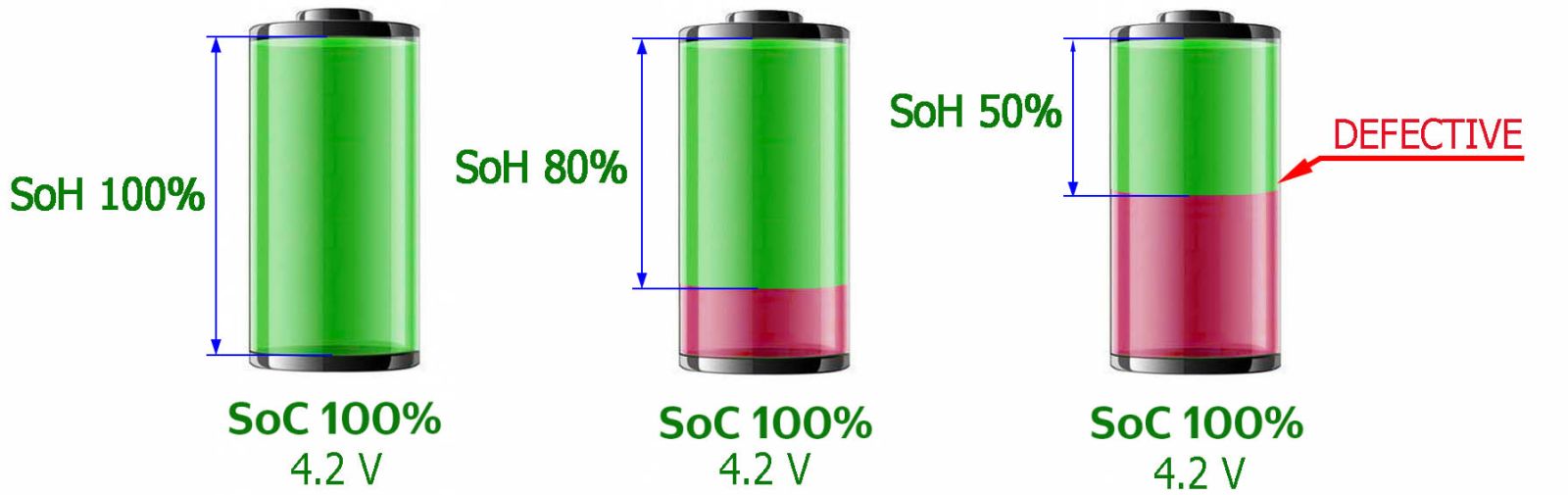

The State of Health (SOH) reflects the level of wear and degradation of the battery. Even if the battery management system operates correctly, natural aging gradually reduces its SOH. Diagnosing this parameter helps to predict the service life and make decisions regarding repair or replacement. To determine SOH, the battery (both the pack and individual modules) must be fully charged and then fully discharged while measuring the amount of energy it delivers. Comparing this value with the nominal (manufacturer’s) specification provides the degree of battery degradation.

3. Module Imbalance (ΔV)

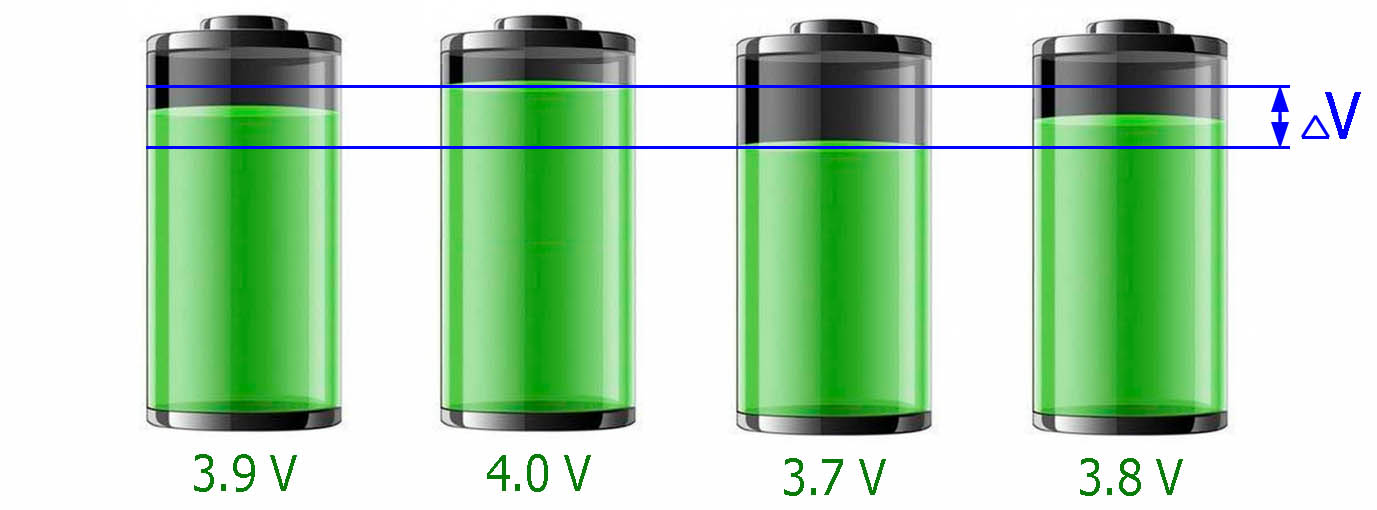

Imbalance is the most common issue in hybrid and electric vehicle batteries and can lead to complete inoperability of the vehicle. Modern batteries consist of dozens of modules, and each module in turn may contain several to hundreds of cells. Over time, the voltage of individual modules begins to diverge. Once this difference reaches a critical threshold, the battery management system will disable the battery, and a warning about high-voltage system malfunction will appear on the instrument panel.

4. Internal Resistance (IR)

Internal resistance is another crucial parameter. It directly affects the battery’s ability to deliver high current for acceleration or to accept electrical energy during fast charging. Even if the overall capacity remains high, increased internal resistance causes battery overheating, reduced efficiency, and unstable operation. Practically, this manifests as power drops during acceleration or rapid discharge under load. Rising internal resistance indicates cell degradation or damage to interconnections. For this reason, IR must always be measured during high-voltage battery diagnostics.

5. Self-Discharge Rate

The self-discharge rate indicates how quickly a battery loses charge when not under load. Increased self-discharge is often linked to degradation of the battery’s chemical composition, electrode materials, or electrolyte. This parameter is essential for detecting hidden issues that may not appear during standard tests. A high self-discharge rate in one module quickly causes battery imbalance, leading to a complete loss of vehicle operability in a short time.

Diagnostic Tools for High-Voltage Batteries: MS800 and MS801

Accurate diagnostics of electric and hybrid vehicle batteries requires specialized testers such as the MS800 and MS801. These tools not only evaluate battery health but also perform balancing and prepare modules for installation.

- MS800 is optimal for workshops handling a large number of hybrid vehicles (Toyota, Lexus, Honda, etc.) as well as EVs requiring modular battery balancing. The tester features 36 independent channels, allowing simultaneous testing of multiple modules.

- MS801 is better suited for diagnosing modern lithium-ion EV batteries, including 48V MHEV systems. The tester can process only one module or battery at a time, but its high discharge current of 90A makes the testing process very fast. The MS801 is ideal for specialists prioritizing speed in battery diagnostics.

.jpg)

Conclusion

Diagnostics of electric and hybrid vehicle batteries relies on a comprehensive analysis of parameters such as SOC, SOH, internal resistance, imbalance, temperature behavior, charge/discharge cycles, and BMS logs. Only their combined evaluation allows for an accurate assessment of battery condition and prediction of its service life.

The use of specialized testers ensures diagnostic precision and is one of the key factors for high-quality repair and maintenance of electric vehicle batteries.