Why do the tie rod ends wear and how can you replace them?

The tie rod connects the steering mechanism and wheels, in addition to the force transmission necessary for the wheel rotation. The steering mechanism is fixed static to car body while the wheels remain bouncing and suspended.

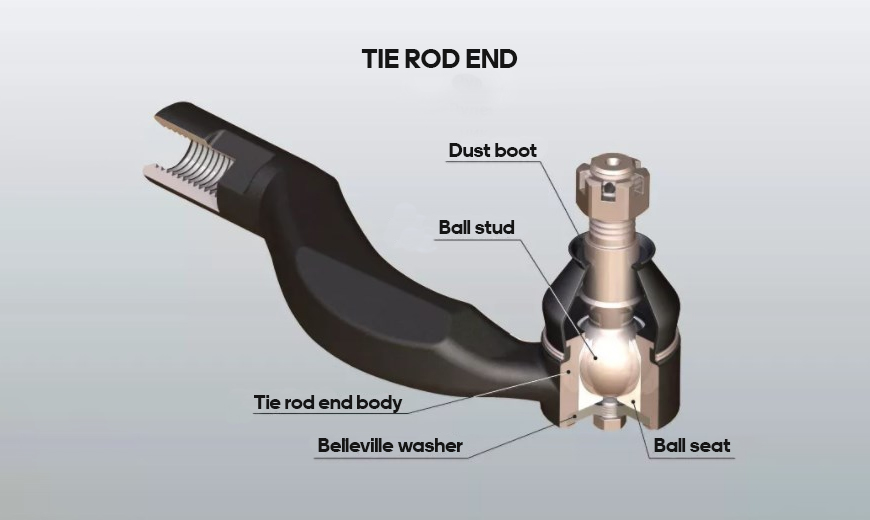

Tie rod end configuration

The tie rods are attached to the steering rack bar by the inner tie rod ends, to the center rod assembly – by the ball joints. The outer tie rod end connects the tie rod and the steering knuckle arm. The tie rods may easily move up and down that enables its proper operation when you drive the uneven road.

The tie rod ends remind the human joints: the sphere of ball stud rotates in the semi-sphere housing that has a bushing and is lubricated with a special grease preventing metal friction. It enables the inclination of the ball stud at a definite angle. The ball joints eliminate the wear and deformation of the rubber dust boots. Due to this design, the movable and integral drive parts. The tie rod ends are pretty wear-resistant, has a long life-span due to the steel ball studs. The bushing is made of the wear-resistant metals, and the body is adonized for a higher corrosion protection.

Why do the tie rods wear – despite of their component reliability?

The tie rods are considered to be the weakest assembly of a car. Mainly, the tie rods fail due to the driver’s fault: the stone and the curb shocks at the high speed that cause the deformation. The other quite common reason of the failure is the ball joint dust cover damage. It results in the moisture or road grime ingression into the joint that causes the sooner failure. That is the main malfunctions that make the driver contact a car service station.

If the tie rod is bent, it may cause the other failures. The wheel alignment appears, the dust boots tear and the tie rod ends break. If a car drove into an obstacle at a high speed, you should visit a car service station where the servicemen will check the tie rod geometry.

Tie rod end failures

If there are failures in the steering system, there will be looseness, knocking, shocks into the steering wheel.

The tie rod end failures may result in:

- shocks into the pedal when you step down on the throttle;

- noise in the wheels when turning on the uneven road;

- the steering wheel rotates without efforts;

- wheel alignment problems.

When the tie rod ends worn out, while the tie rods bounce, the gap will be more than the nominal 1.5 mm.

Important! The recovery of the tie rod ends is possible but is not recommended because the rebuilding won’t get the expected results. It’s only the bushing that might be replaced while the sphere will remain the same. Again, the bushing should be pressed, and in the end, there still will be noise in tie rod end.

How to replace the tie rod and tie rod ends properly?

When the tie rod ends fail, they have to be replaced. The replacement steps are as follows:

- lift a car with a car jack and remove the front wheels previously blocking the steering wheel;

- loosen the nuts that fix the tie rod end to the tie rod;

- remove the r-pin;

- remove the nut between the tie rod and knuckle;

- using the ball joint puller, press out the tie rod end;

- prior to the dismounting, make a marking to set the thread level;

- as soon as the dust boots are dismounted, unscrew the tie rods.

Important! Once all the operations are finished, you should make the wheel alignment. If you skip this step, the tyres will wear unevenly, and it will be difficult to drive a car. Any interference into the steering system requires the wheel alignment followed.

The replacement won’t be a challenge if:

- the special-purpose equipment will be used;

- the new tie rod ends are of high quality.

The described above replacement is quick and of low cost. Thus, if you are not experienced in the automotive repair or doesn’t have the special tools, contact the car repair shop that deals with the steering systems.