Modern Vehicle Diagnostics: Key Aspects

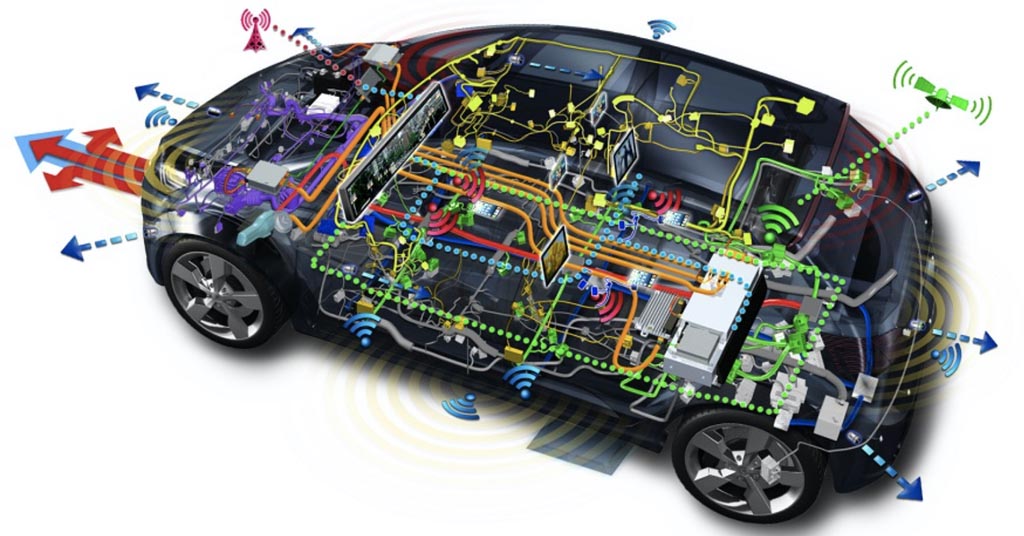

Today’s vehicles are highly advanced systems that combine mechanical components, multiple engine types, dozens of sensors, control units (ECU/ECM), and complex software. Even a minor issue can impact the performance of an entire system and render the vehicle inoperable. This is especially relevant as hybrid and electric vehicles are becoming more common on U.S. roads alongside traditional internal combustion engine (ICE) vehicles. Accurate diagnostics is a critical step toward safe operation and avoiding costly repairs. But diagnostics isn’t just about pulling error codes — it’s a comprehensive process involving specialized tools, software, and in-depth technical expertise.

A Smarter Approach to Diagnostics

Effective diagnostics relies on a few key principles that help pinpoint problems and ensure accurate assessment of a vehicle's condition:

Systems Thinking: A vehicle should be viewed as a network of interconnected systems. A failure in one component can have ripple effects on others.

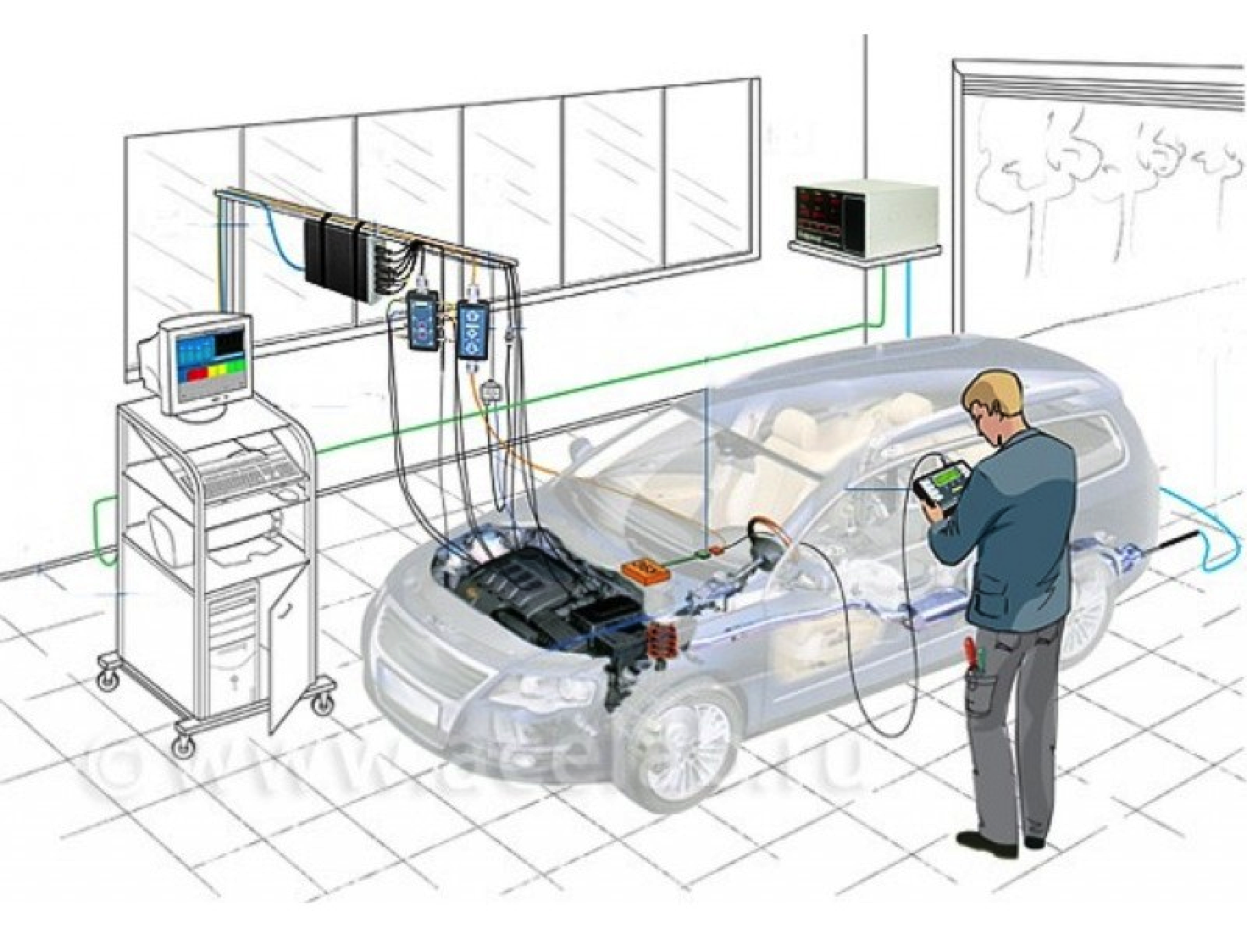

Use of Professional Equipment and Software: High-quality scan tools, test benches, and component testers make it possible to gather precise data quickly and accurately to determine the root cause of a fault.

Hands-On Experience: T Tackling more complex repair jobs builds practical experience that’s crucial in identifying and solving unusual or non-obvious issues. It also encourages ongoing learning of new diagnostic tools, software platforms, and methods.

Staying Current: Modern vehicles are heavily integrated with electronics — almost every component, from the engine to the headlights, is controlled by an ECU. Since these systems are software-driven and receive updates, technicians need diagnostic tools with updateable software to stay relevant and effective over time.

Implementation and Improvement of Safety Protocols. Electric and hybrid vehicles introduce new safety challenges. These vehicles contain high-voltage components like battery packs, inverters, and electric climate systems that require a completely different approach than traditional ICE vehicles. Safe diagnostics demands specialized training and strict adherence to high-voltage safety protocols. Technicians must understand lithium-ion battery systems, cell balancing, state-of-charge analysis, residual capacity testing, and temperature monitoring procedures.

Types of Vehicle Diagnostics

Accurate diagnosis requires a combination of multiple diagnostic strategies:

- Computer (OBD-II) Diagnostics: The foundation of modern diagnostics. Fault codes (DTCs) are read and real-time data (Live Data) is analyzed from ECUs. This allows evaluation of systems like ABS, transmission, suspension, climate control, and airbags.

- Mechanical Diagnostics: Includes visual inspections and measuring technical parameters such as compression, oil pressure, refrigerant pressure, valve clearances, and vibration levels, etc.

- Road Test Diagnostics (Test Drive): Helps identify problems that only occur under driving conditions. This is often paired with real-time data monitoring to better understand how systems behave on the road.

- Bench Testing of Components: Involves testing systems and components outside the vehicle to eliminate interference from other vehicle systems. Bench diagnostics can reveal detailed data not accessible via OBD tools alone.

The Role of the Diagnostic Technician

Today’s diagnostic technician is more than just a mechanic — they’re a hybrid of electrician, computer technician, and mechanical expert. A skilled tech must be able to:

- Use advanced diagnostic equipment;

- Read wiring diagrams and system schematics;

- Interpret trouble codes and live sensor data;

- Identify intermittent or hidden faults;

- Assess wear and tear based on mileage, driving habits, and environmental conditions.

Continuous training is a must. As automotive technology evolves rapidly — with new communication protocols, sensors, and systems — staying up to date is essential for accurate and efficient diagnostics.

Conclusion

Modern vehicle diagnostics is a high-tech, precision-driven process that’s essential for both safe operation and proper maintenance. As vehicles become more complex and electrified, shops must invest in advanced diagnostic tools and training to keep up.

MSG Equipment offers a wide range of professional-grade diagnostic solutions — from test benches to electronic testers — all with updateable software to keep your tools current. We also provide hands-on training courses that help technicians stay ahead of industry trends and confidently diagnose and repair today’s complex vehicle systems.