Simple and straightforward about how a car engine works

Many will say, why, say, why know about the structure of the engine, we do not go into the intricacies of electrical appliances, and just talk on the phone or heat food in the microwave oven. But with cars, things are a little different. If the microwave breaks down – you heat up dinner on the cooker, and if the engine breaks down – the life and safety of you and your loved ones depends on it.

Why to know the structure of the car engine

On how well you understand the design features of each node of the car depends on how responsive you will react to changes in their performance. It depends on whether you will hear an uncharacteristic knock in a steering rack, suspension, valves, whether you will distinguish whistling of a belt of the generator, brake pads, whether you will be able to carry out diagnostics and eliminate failures in time. In other words, your ability to feel the car depends on your theoretical and, if possible, practical knowledge of the structure, purpose and functioning of its individual elements.

Any engine – is a device that converts any kind of energy into mechanical energy. According to the criterion of localisation of the heat source and the combustion process, two classes of engines are distinguished: internal and external combustion engines.

The most common type of motor in the automotive industry is considered an internal combustion engine (abbreviation – internal combustion engine). The name makes it clear that it is a type of motor in which fuel is burned internally, converting one type of energy (thermal) into another (mechanical).

An internal combustion engine is the most common type of motor in the automotive industry.

In turn, according to the method of energy conversion, internal combustion engines are of these types:

- piston;

- rotary-piston;

- liquid rocket;

- gas-turbine;

- air-jet.

They are also divided by the number and arrangement of cylinders, by weight and working volume (light, medium, heavy), by type of cooling (with liquid cooling system and with air cooling system), ignition, etc.

Based on type of fuel used, internal combustion engines can be divided into petrol, gas and diesel. Petrol engines, in turn, are divided into:

- carburettor (in these, the combustible mixture is prepared in the carburettor, fed and enters the cylinder, where it is compressed and ignited);

- injector (in them with the help of injectors fuel is injected into the cylinder or intake manifold).

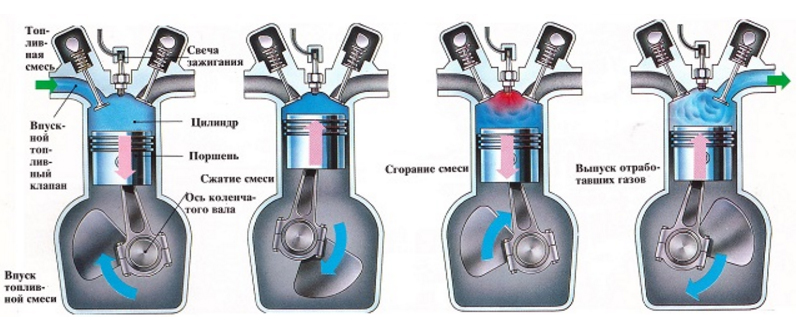

The piston motor operates cyclically. The duty cycle is the periodically repeated sequential processes that occur in each cylinder. The unit of the duty cycle is what is known as a cycle cycle. This is the process that takes place in the cylinder during one stroke of the piston. In simple terms, it is one action or work operation in a single cylinder.

Engine construction on the example of a petrol internal combustion engine

The main part of the engine is the cylinder. On top of it is the cylinder head, in the middle of which there is a hole in which the spark plug is placed. On one side of the head is a channel for the inlet of the combustible mixture into the cylinder space, and on the other – channel for the release of gases that have already been exhausted. These channels are closed, respectively, by the inlet and exhaust valves.

Other parts are the piston and piston rings, and the connecting rod. The connecting rod has an upper non-separable head and a lower separable head (separating into two even parts). The connecting rod is joined to the piston by the split head and is secured by the piston pin.

Another element is the crankshaft of the engine. It has two bearing (main) journals, against which it rotates, and a connecting rod journals, which are joined to the lower connecting rod head by nuts and bolts.

The crankshaft is another element.

The piston, combined with the connecting rod and crankshaft, is placed in the cylinder, forming the main working unit of the engine.

All this – the structure of a single-cylinder motor. In reality, the number of cylinders in a motor can vary from 2 to 8. There are also 12-cylinder engines (W-shaped), in which 6 cylinders are in the left block, 6 – in the right.

These are all – the structure of a single-cylinder motor.

Basic Concepts

The topmost position of the piston – top dead centre (TDC).

Lowest piston position – bottom dead centre (BDC).

Distance between top dead centre and bottom dead centre – piston stroke.

Piston stroke.

The portion of the cylinder volume that remains above the piston when it is at top dead centre – combustion chamber volume.

Cylinder volume that remains above the piston when it is at top dead centre – combustion chamber volume.

The volume of the cylinder when the piston is at TDC – the total volume of the cylinder.

The portion of the cylinder volume that lies between top and bottom dead centre – cylinder displacement. It is from this indicator depends on the power of the engine. Between them there is a direct relationship, ie, the greater the working volume of the cylinder, the more power of the engine. The power itself is measured in horsepower or kilowatts. 0.735 kW equals 1 horsepower (hp).

Important! The sum of the working volumes of all the engine cylinders without exception – is its litreage (another name: engine displacement). This characteristic is measured in litres.

According to the litre capacity, passenger cars are classified into car classes:

- small (engine displacement of which is less than 1.1 litres);

- small (volume varies between 1.1 and 1.8 litres);

- medium (ranging from 1.8-3.5 litres);

- large (with a volume of more than 3.5 litres).

The result of dividing the total cylinder volume by the combustion chamber volume – compression ratio.

In the following articles we will explain the principle of operation of internal combustion engines. Study the peculiarities of the design and operation of the car and have a good journey! The main section of the site presents equipment for service stations.

We will tell you about the principle of internal combustion engines.