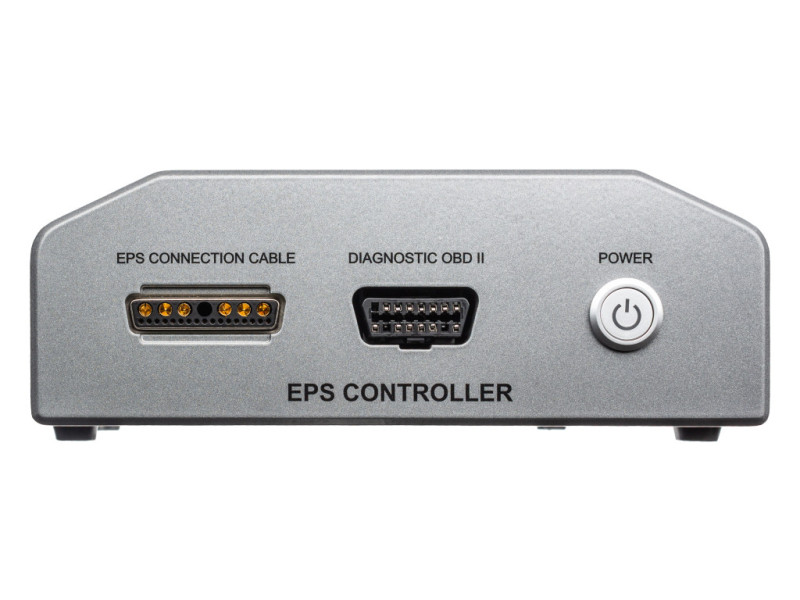

MS561 PRO

Tester for diagnostics of electric power steering units

The MS561 PRO tester is used for diagnosing and repairing EPS steering racks, columns, and electric hydraulic power steering (EHPS) pumps. The tester also allows diagnosing torque sensors separately from the steering rack. It simulates a car for the electric power steering, enabling it to run independently of the vehicle’s electrical system (on a bench mode) and obtain the necessary diagnostic information:

- Current consumption on two terminals K15 (ignition) and K30 (motor), additionally showing the correct (normal) current consumption for the unit under test;

- Current ("live") data from the control unit;

- DTC error list, with the ability to erase them;

- Unit information: VIN, hardware version, software version, etc.

The tester also features a set of special functions* for repairing electric power steering systems:

- Flash programming (allows clearing errors that cannot be erased by regular error deletion). Relevant for Ford, Audi, VW, Porsche.

- Parameter loading (allows configuring the steering rack for a specific vehicle.). Relevant for VAG group.

- VIN change for GM racks.

- Virginizing – clearing the rack’s association with a vehicle (allows installing racks from another vehicle). Relevant for Renault/Nissan.

- EEPROM reading/writing.

- Software restoration of faulty control units.

* The list of units with available special functions depends on the specific unit and vehicle. This list is constantly expanded with new tester software updates.

Features:

- Compatibility with any data transmission protocols.

- Dynamic CAN indication, allowing real-time monitoring of the correctness and integrity of the connection to the power steering system.

- Unit database with OEM number search capability.

- Displays the pinout of the unit connector for correct connection to the tester.

- Non-standard OBDII connector pinout can be set.

- Diagnosis of units with a maximum current consumption of 100A.

- Regular software updates.

New steering units:

- KI401 KIA EV6 2021-

- SK701 SKODA Octavia A8

- VO406 VOLVO C40 [2021-], POLESTAR Polestar 2 [2019-]

- FI401 FIAT Ducato 2014- (Only Identification + DTC)

- FO708 Ford Transit Courier 2023- (Only Ident+DTC, SECOC!)

- FO431 FORD Flex, Taurus (AA53 firmwares)

- FO425 FORD USA Fusion 2010-2012 (AE5C firmwares)

Diagnostic functions for:

- PE303, PE313 – Peugeot/Citroen pumps

- PE405 PEUGEOT 207

Added programming and firmwares for:

- VW417, VW416 – Parametrization (Dataset uploading)

- FO705 FORD Focus 4 (JX6C firmwares) +AS Built

- FO706 FORD Kuga 3 / Escape (LX6C firmwares) +AS Built

Diagnostic functions for:

- SK302 VW Polo / Skoda Fabia, etc…

DTC, Identification, Live data, Coding, Sensor switching

- Fixed some bugs

- New steering units:

- RI401 Rivian R1S, R1T (With DTC reading function)

- TY407 Toyota Highlander 2019-

EEPROM read/write functions for:

- VW416 VW Passat B8 (Development code 1 DTC fixing)

Diagnostic functions for:

- VW417 VW Crafter (Programming, DTC, Live data)

EEPROM read/write functions for:

- LR402 Land Rover Sport & similar ECUs

- FI711, FI713, JP701, JP702, JP703 (C1009 DTC fixing)

New steering units:

- VW301 VW Touareg hybrid 11-17; Porsche Panamera, Cayenne

- RE401 Renault Kangoo 3 2021-

- AC405 ACURA RDX 2018-

- CH403 CHRYSLER PACIFICA 17-

- FO707 Ford Mustang Mach-e

- TY412 Toyota Venza 20-

Diagnostic functions for:

- TS404 Tesla Model 3/Y

- TS405 Tesla Model S/X

- FI711 Fiat Tipo/Egea

Special functions:

- VW415 – Converting eeprom dumps from/to LHD<->RHD

- RE703 – VIN reading/writing, Virginizing

- FI711 – Steering angle calibration

New steering units:

- CI406 TOYOTA ProAce City 19-; PEUGEOT Rifter 18-; CITROEN Berlingo 19-

- AR702 ALFA ROMEO TONALE 2023-; DODGE HORNET 2022-

Diagnostic functions for:

- FI711 Identification / DTC + Steering angle calibration

Added programming and firmwares for:

- FO434 Ford Transit 2017- (+Programming ASBuilt calibrations)

- JA401 Jaguar F-pace

- VW416 VW Passat B8

EEPROM read/write functions for:

- VW415 VW Golf7, etc...

- DG401 DODGE CHARGER / CHALLENGER

- DG403 DODGE DURANGO / JEEP GRAND CHEROKEE 17-

- DG404 DODGE RAM 19-

VIN read/write for:

- CH401 Chrysler 200

- JP401 JEEP Cherokee KL

- DG405 DODGE Dart

- Added programming and firmwares for FO405 FORD Connect (18-22)

- New Flexray Firmware (00014) - Fix for Mercedes AMG versions couldn't start

- Fixed DG402 picture

- Added Live data for PH402 (Porsche Macan)

- Added DTC description for AU406, AU409 (All flexray AUDI)

New steering units:

- IN403 Infiniti QX50 18-

- SU410 Subaru Outback 19-

- IN302 Infiniti Q70 (13-19)

- JP303 JEEP WRANGLER IV JL (17-)

- FI303 FIAT DUCATO (14-)

- NI405 NISSAN Qashqai (21-) +VIN Virginizing

Diagnostic features (Identification / DTC / Live data*) for:

- All Audi / Porsche

- All Flexray BMW

- All Flexray Mercedes-Benz

- FO422 Ford Ranger + programming

Added support for new universal CAN-FD Cable MS-35671

New Flexray Firmware (00013) - Fix for Mercedes W222

Fords Diagnosing and Programming for FO414 (Focus 3), FO417 (Explorer 10-15), FO430 (Explorer 15-20), FO422 (Mondeo 5 / Galaxy / S-Max).

All necessary functions like ECU Info, DTC Reading / Erasing, Live data / Programming and EEPROM Reading completed.

New steering units:

- MA707 (MAZDA MX-30) MA404 (MAZDA CX-60) with diagnostic functions

New cables:

- MS-36102 (145R) for MA404

- MS-35103 (146C) for MA707