Save the environment with the MS900 stand

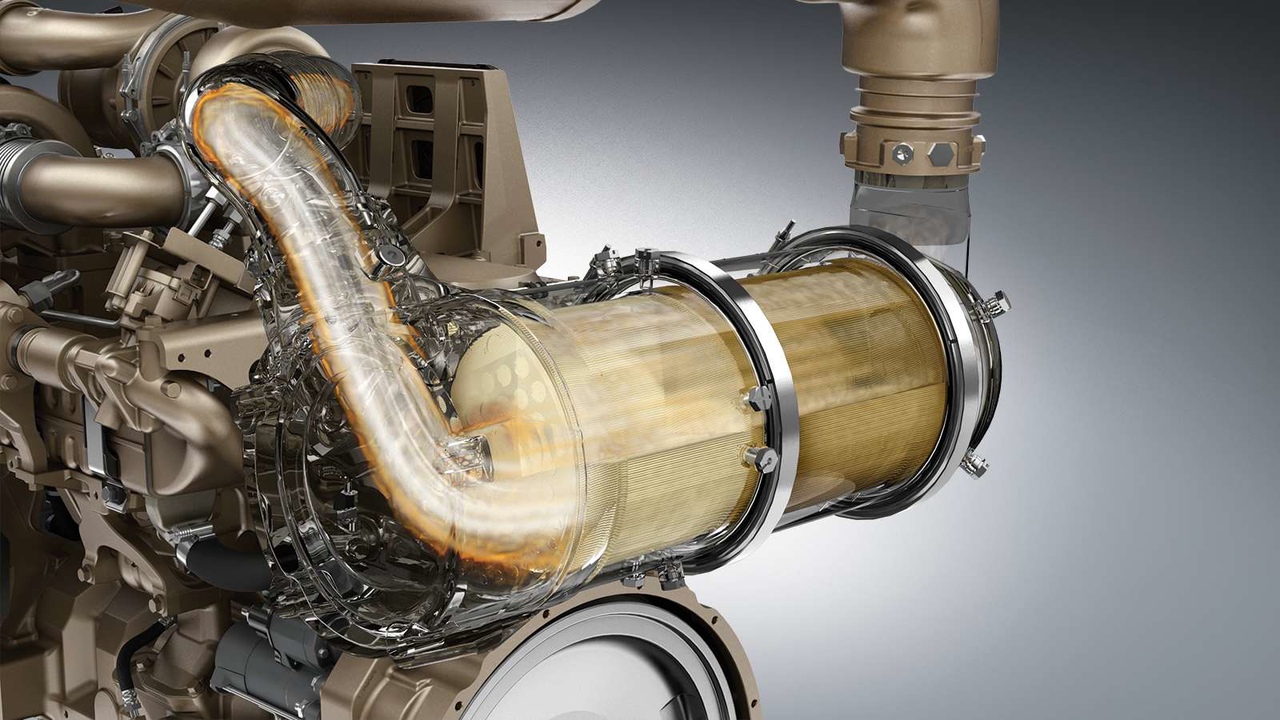

Diesel engines have the highest efficiency compared to other types of internal combustion engines. That is why they have found wide application in commercial transport and play a crucial role in the country's economy by facilitating the transportation of various goods. However, preserving the environment is of decisive importance for the well-being of both current and future generations. The introduction of diesel particulate filters (DPF) in vehicle design has been a significant step forward in the fight against air pollution, reducing emissions from diesel engines.

Over time, DPFs get clogged with soot and ash, which affects the efficiency and performance of the vehicle. Regular cleaning of the DPF is necessary to maintain optimal functionality. Long-term regular DPF cleaning provides substantial cost savings and has a positive impact on the environment.

How is the issue of DPF cleaning solved?

To address the task of DPF cleaning, various methods have been developed, such as thermal regeneration, chemical cleaning, pneumatic cleaning, ultrasonic cleaning, and water flushing. The most widespread method is chemical cleaning of the DPF due to its effectiveness and simplicity in removing soot and other contaminants.

During chemical cleaning of the DPF, the used cleaning solution needs to be properly disposed of. This means an additional technological process is required to remove chemically active substances from the solution before releasing it into the sewage system. Consequently, additional expenses are incurred. In practice, the used cleaning solution is often discharged into the sewer without treatment because the wastewater treatment technologies currently in use are not designed to remove detergents that dissolve well in water. As a result, a large amount of chemically active substances end up in water bodies, soil, and groundwater, causing irreparable harm to the ecosystem.

How is the issue of DPF cleaning solved with the MS900 stand?

The MS900 stand utilizes a combined hydro-pneumatic method for cleaning DPFs. The DPF is washed with a stream of warm water that periodically changes its direction. Compressed air is periodically injected into the water stream, ensuring the necessary flow turbulence. This allows for high-quality DPF cleaning without the use of chemical cleaning agents.

The stand's design includes a hydrocyclone that collects the majority of the soot and ash, which is then disposed of with household waste. The remaining portion of the soot and ash, along with the used water, is discharged into the sewage system. Such wastewater can be treated by existing treatment plants. Thus, we obtain a clean DPF without harming the environment.

Conclusion:

Although chemical DPF cleaning methods are effective for maintaining the filters' functionality, their potential negative impact on the environment must be considered. The implementation of the MS900 stand in auto repair shops for DPF cleaning will extend the lifespan of DPFs, contribute to environmental preservation, and ensure the efficiency and durability of diesel engines.